The balance between upholding security and maintaining privacy can be tricky to sustain when deciding upon a suitable solution for monitoring a location. Surveillance cameras may not be the right option. The data they capture is extremely specific and can divulge personal details. This can cause issues with privacy should the footage be misused. Instead of utilizing these cameras, passive infrared (PIR) detection may be the way forward. Sensors that use PIR hone in on infrared radiation rather than record videos or images. Join us as we look at PIR sensors and delve into what helps them to be privacy-friendly.

Defining PIR Detection

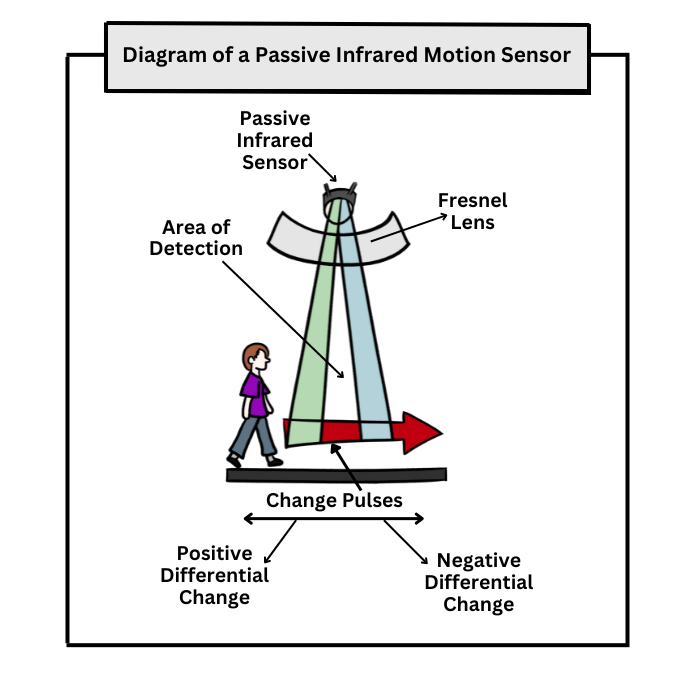

Thanks to their capability to identify infrared radiation, passive infrared sensors tend to be applied to motion detection. Infrared radiation, a form of heat energy, is released from objects that hold a temperature higher than absolute zero. When the PIR sensor is placed in an environment, it’s able to identify differences between the levels of infrared in the location and any objects that enter into it. By pinpointing these changes, PIR sensors are able to detect movement.

The incorporation of thermopiles help PIR sensors to identify any variations in temperature. Thermopiles are made up of thermocouples that are attached either in parallel or series. They can recognize the infrared radiation that occurs from objects that are warm, such as animals or people. Should one of these objects come into the location monitored by a PIR sensor, its thermopile will note a change in the infrared radiation. It will then produce a small voltage in response to the object’s heat. This voltage alteration is read by the sensor as motion. From this, it will produce a response, like setting off an alarm or turning on a light.

Being imbued with the ability to detect motion means that PIR sensors are used within a variety of applications, such as security systems, smart home devices, and automatic lighting. PIR sensors are even found in nursing homes, delivering alerts about inactivity and activity. They can monitor sleep patterns and are used to detect any falls that take place.

Preserving Privacy With Passive Infrared Detectors

Privacy is a factor that will affect your choice of motion detector. These devices keep track of the movement of people in a space. Consequently they can gather sensitive information about them, including their routines and behaviors. If not handled carefully, an invasion of privacy can occur. It’s important to pick a motion detector that can establish privacy, and thus help people feel at ease in its presence. PIR sensors are known as privacy-friendly devices, unlike other devices like microphones or cameras.

1. No Imagery or Audio

PIR sensors solely identify infrared radiation and are only able to understand if alterations in heat occur. They cannot keep track of any audio or imagery. Therefore, the problem of voice identification or facial recognition does not need to be worried about. PIR sensors can help preserve anonymity, ensuring that there is nothing captured that would define an individual. These sensors can only detect that motion has occurred, rather than that a specific someone has caused the motion to take place.

2. Data Breaches

If a motion detector is the target of a data breach, there’s the risk of sensitive information being leaked. Systems that incorporate microphones or cameras could end up showing:

- Vulnerable areas in security

- The location patterns of different people

- Personal spaces like bedrooms, bathrooms, and homes.

PIR sensors cannot provide identifiable information, such as visuals. Ergo should a data breach occur, there is less chance that it will disclose personal data.

3. Simplicity

The simplicity of PIR sensors is a strength when it comes to privacy. It delivers a binary output, reacting to movement by generating a signal that’s either “on” or “off”. PIR sensors do not hold onto complicated data. Therefore, it’s unlikely that sensitive data could end up being revealed.

4. Sensitivity

A helpful attribute of PIR sensors is their configurable sensitivity. Their sensitivity can be altered to disregard low heat signatures, thus they will not be triggered unnecessarily. The adjustability of a PIR sensor’s detection capacity means they can deliver a level of coverage that will not encroach upon privacy.

5. Localized Processing

Data from a PIR sensor does not need to be transmitted externally to be processed. Instead, as the motion detection occurs in the PIR sensor, it’s able to undertake localized processing. Ergo, none of the motion data will need to be sent over networks. This can lower the possibility of sensitive information being accessed without permission.

Establish PIR Detection As Your Choice of Privacy-Friendly Motion Sensing

Your selection of security should provide you with a sense of confidence, not cause you to experience more concerns relating to privacy issues. PIR sensors can help you to keep an eye over an environment, alerting you to any changes in heat levels without intruding upon privacy.

If you want to ensure your security is the best it can be, we have thermopile detectors listed on our website that can help you achieve this ambition. PIR systems can incorporate these detectors. Their extensive lifespan, reduced energy consumption, and robust sensitivity will ensure they’ll be effective when you task them with monitoring your space. You can find our thermopile detectors used for security here.